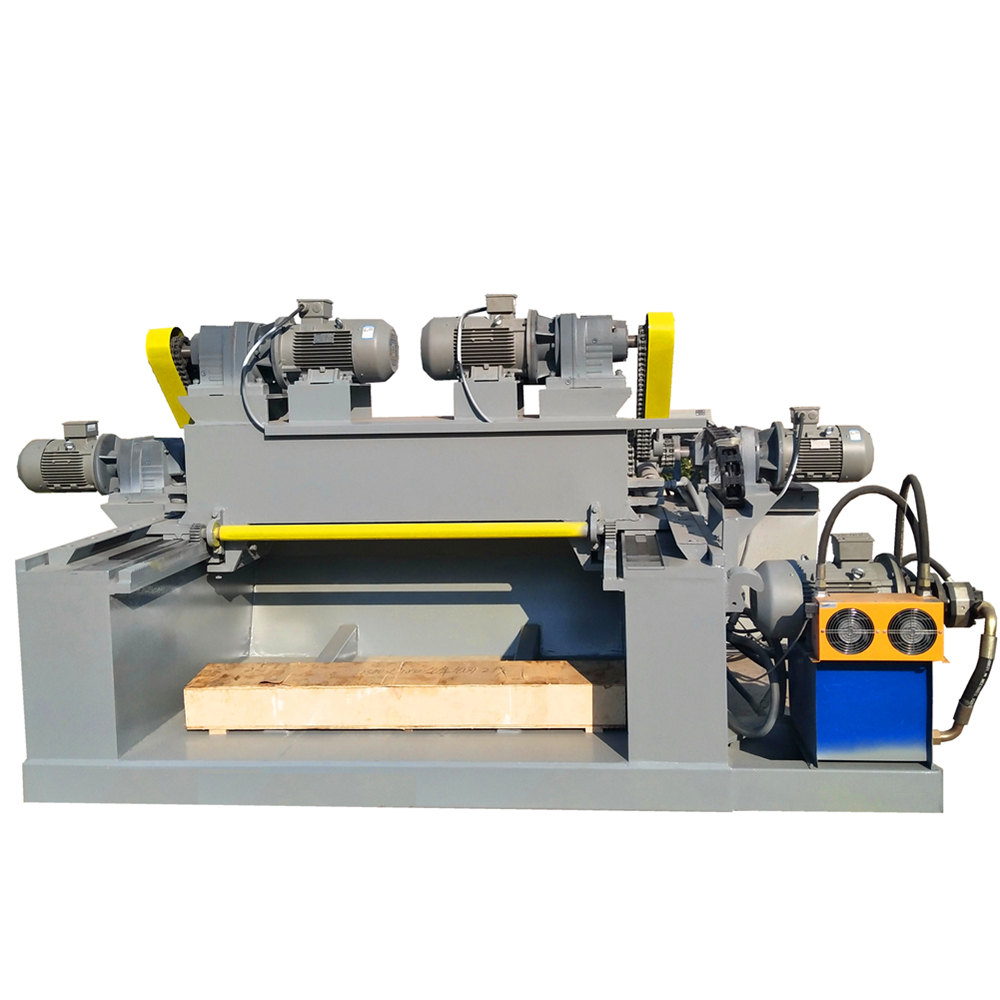

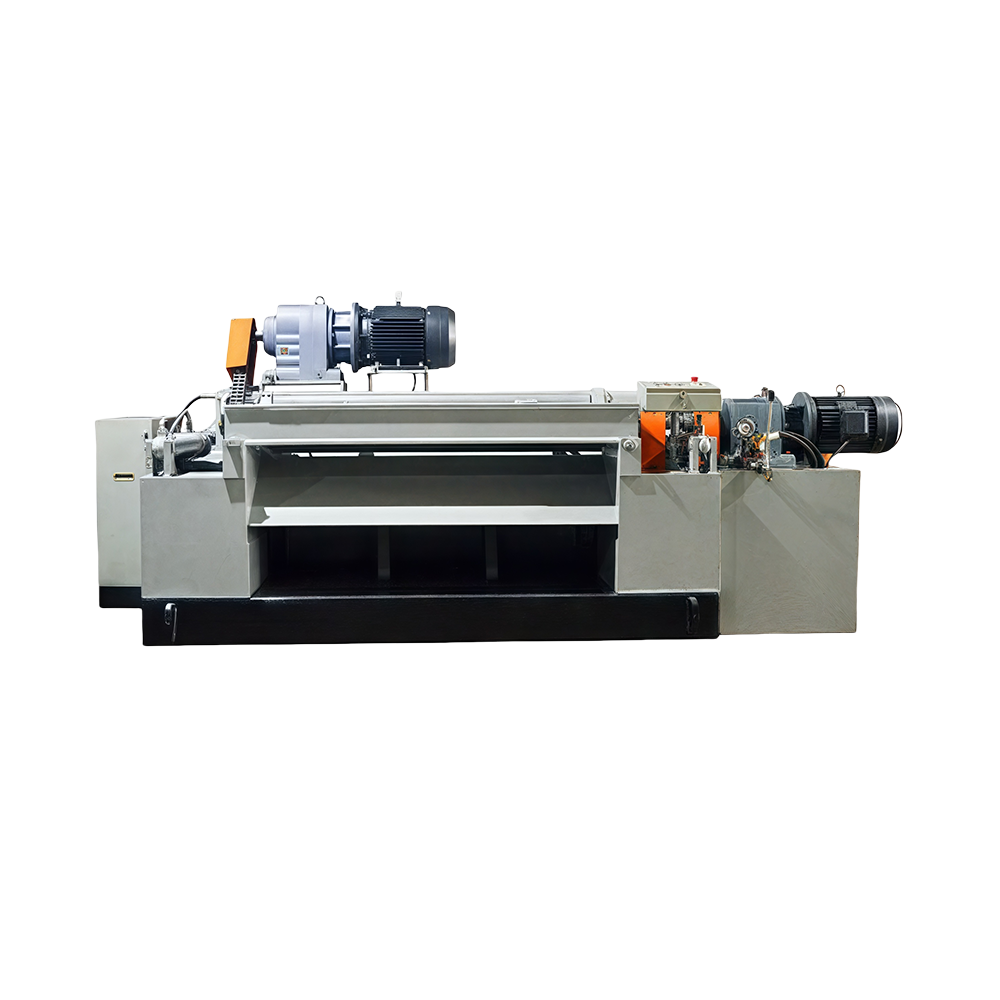

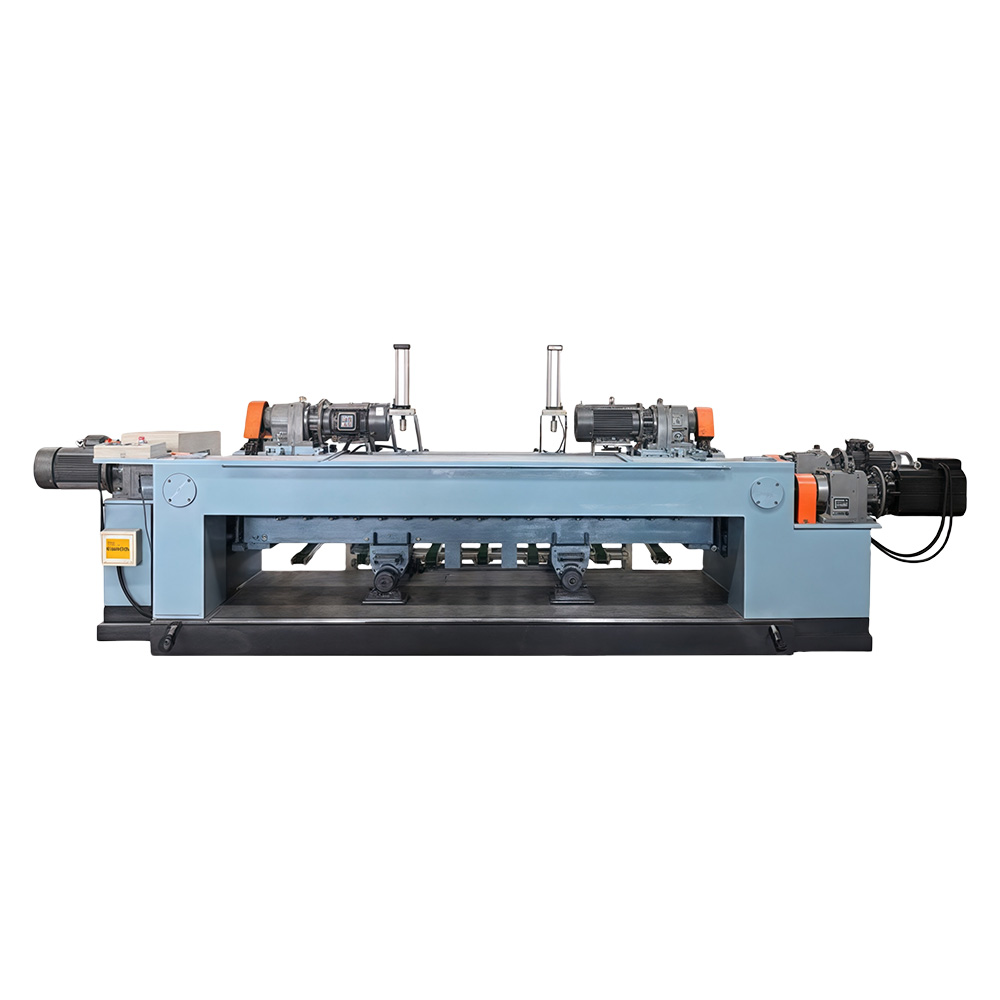

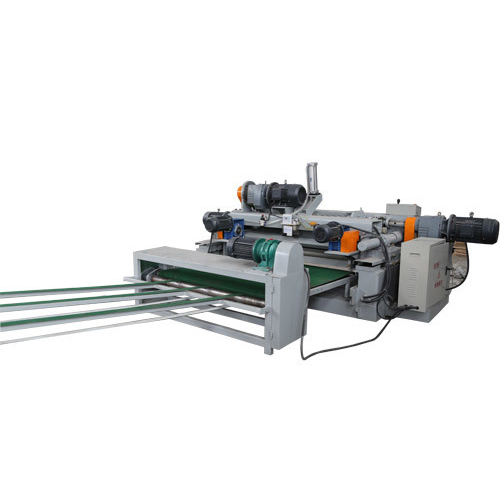

Splicing machine

【Technical function】

The skin receiving machine is mainly composed of conveying system, embryo formation system, gluing system and pressure device, which is mainly used for continuous formation and connection of multi-layer veneer, so that the veneer is arranged and preliminically fixed in a certain order and manner, forming a slab with certain strength and stability, and preparing for the subsequent process. Through the processing of the peeling machine, the degree of automation, production efficiency and product quality of plywood production can be improved, and the error and labor intensity of manual operation can be reduced.

Product application value and advantages

【Reduce waste】

it can realize the automatic conveying, forming, gluing and preliminary connection of the single board, reduce manual intervention and improve production efficiency

【High production efficiency】

continuous veneer formation and connection, can meet the needs of large-scale production

【Precision control】

Through the control system and mechanical structure, the conveying speed, position, gluing amount and pressure of the board are accurately controlled to ensure the consistency of accuracy and quality

Product detailed parameters

|

Processingthickness |

1.2-5.0mm |

|

Processing width |

968-1270mm |

|

Feeding speed |

32m/min |

|

Length of knife |

1350mm |

|

Motorpower |

18KW |

|

Ocuppy area |

11.5*3.2m |

You Might Also Like