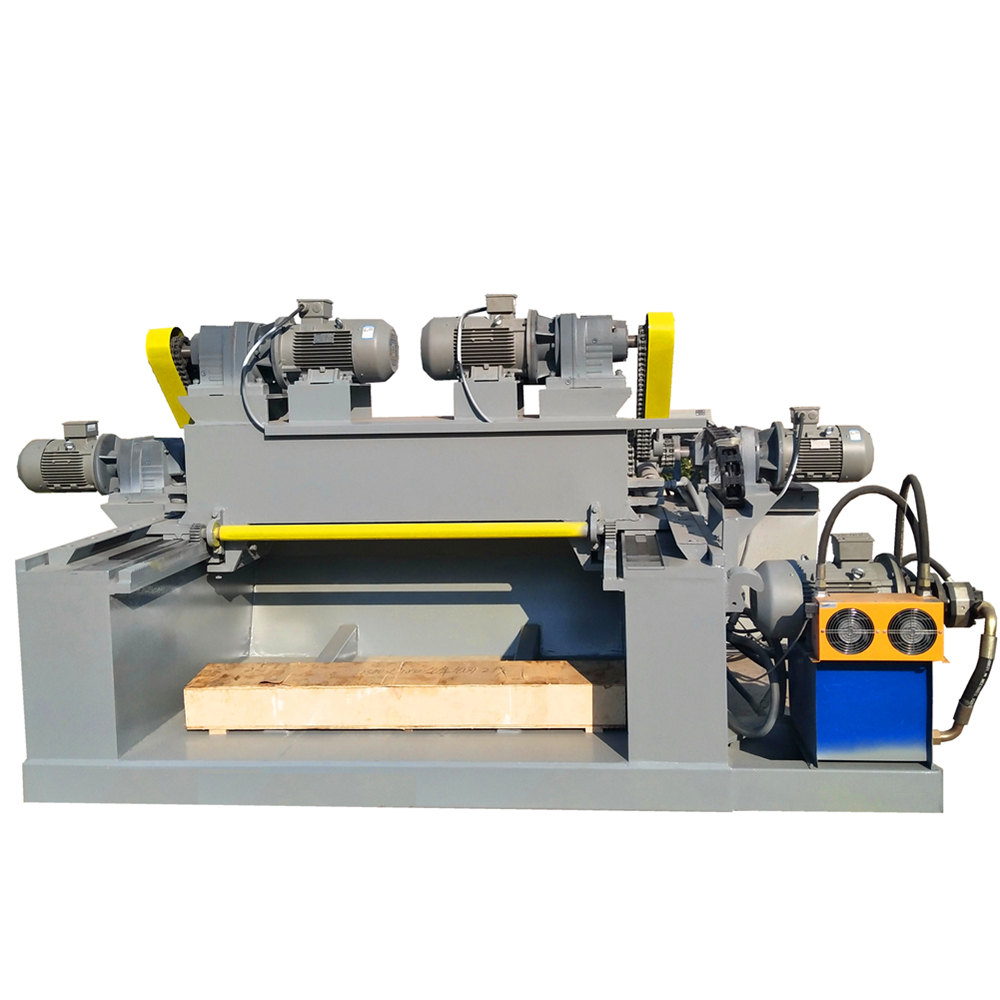

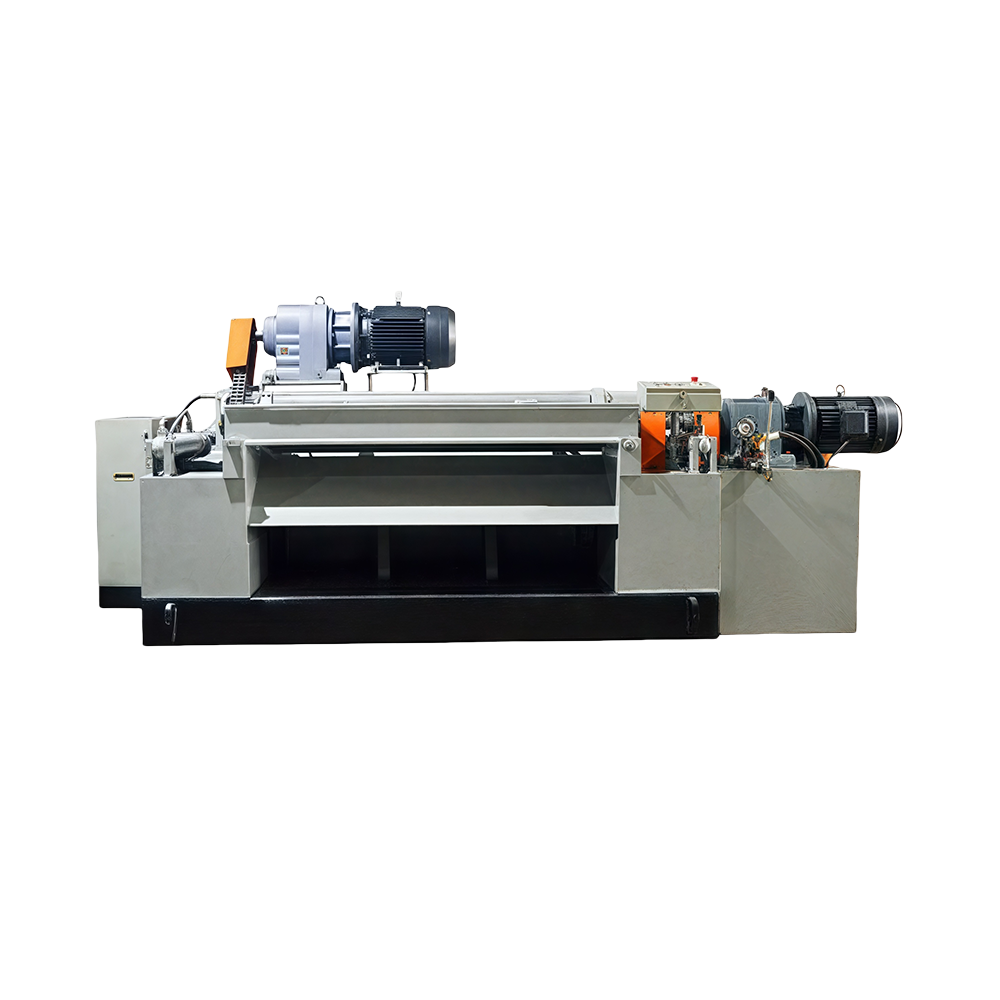

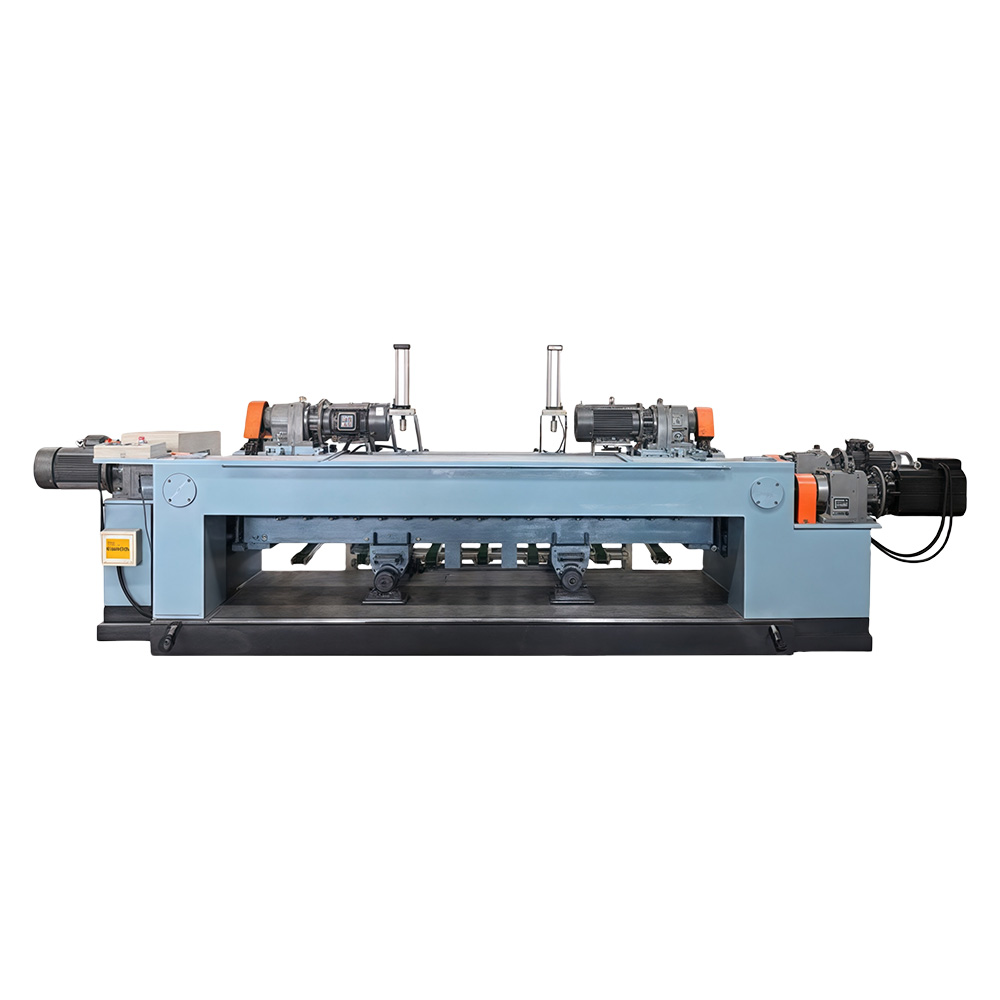

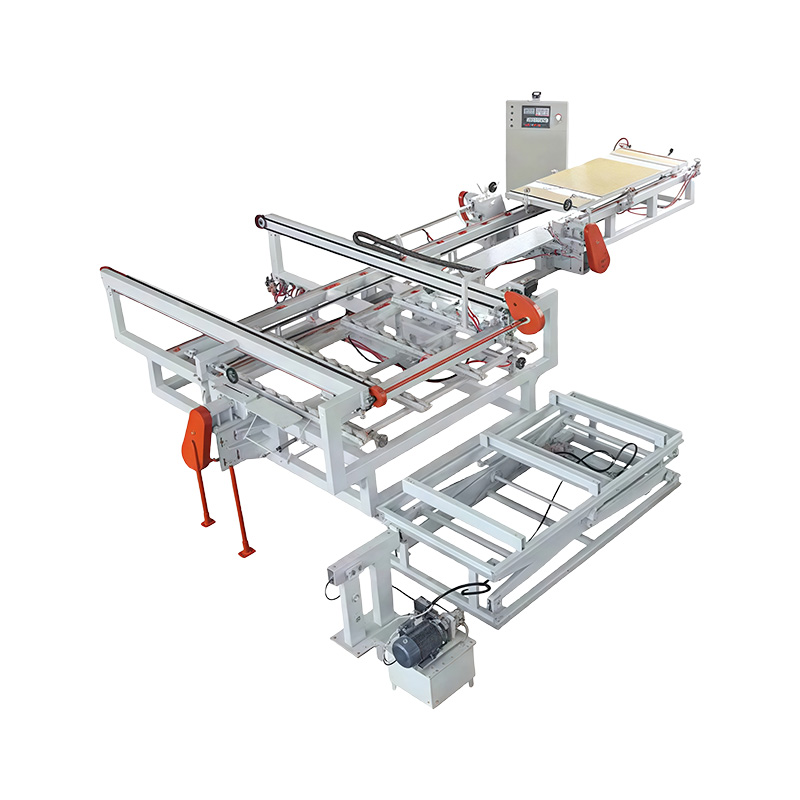

Rotary cutter

【Technical function】

The rotary cutting machine is composed of frame, clamp/roll system, tool holder and tool, transmission system, control system, etc. It is mainly used for rotary cutting of raw wood into continuous veneer or thin wood chips. It is the core equipment for the production of wood composite materials such as plywood and LVL veneer laminate. Widely used in furniture manufacturing, architectural decoration, packaging and other industries.

Product application value and advantages

【Reduce waste】

The cardless machine can process the wood core to 1cm, reducing waste

【Diversified production】

CNC models support high precision, multi-thickness fast switching, to meet diversified production needs

【High degree of automatism】

High degree of automation, reduce manual operation intensity

Product detailed parameters

|

Double roll diameter |

125mm |

Roller motor |

RV110 reducer *1 |

|

Roller motor |

R87 hard gear reducer *2 |

Roller motor power |

2.2KW |

|

Roller motor power |

7.5kw |

Rotary cutter size |

1500 * 160 * 16 (mm) |

|

Feed motor |

R87 hard gear reducer *1 |

Cutting thickness |

1.0-3.8mm |

|

Feed motor power |

11kw servo |

Cutting speed |

45m/min |

|

Guillotine motor |

RV110 reducer *1 |

Wood diameter |

32~500mm |

|

Guillotine motor power |

2.2KW |

Total mass |

5.5T |

You Might Also Like