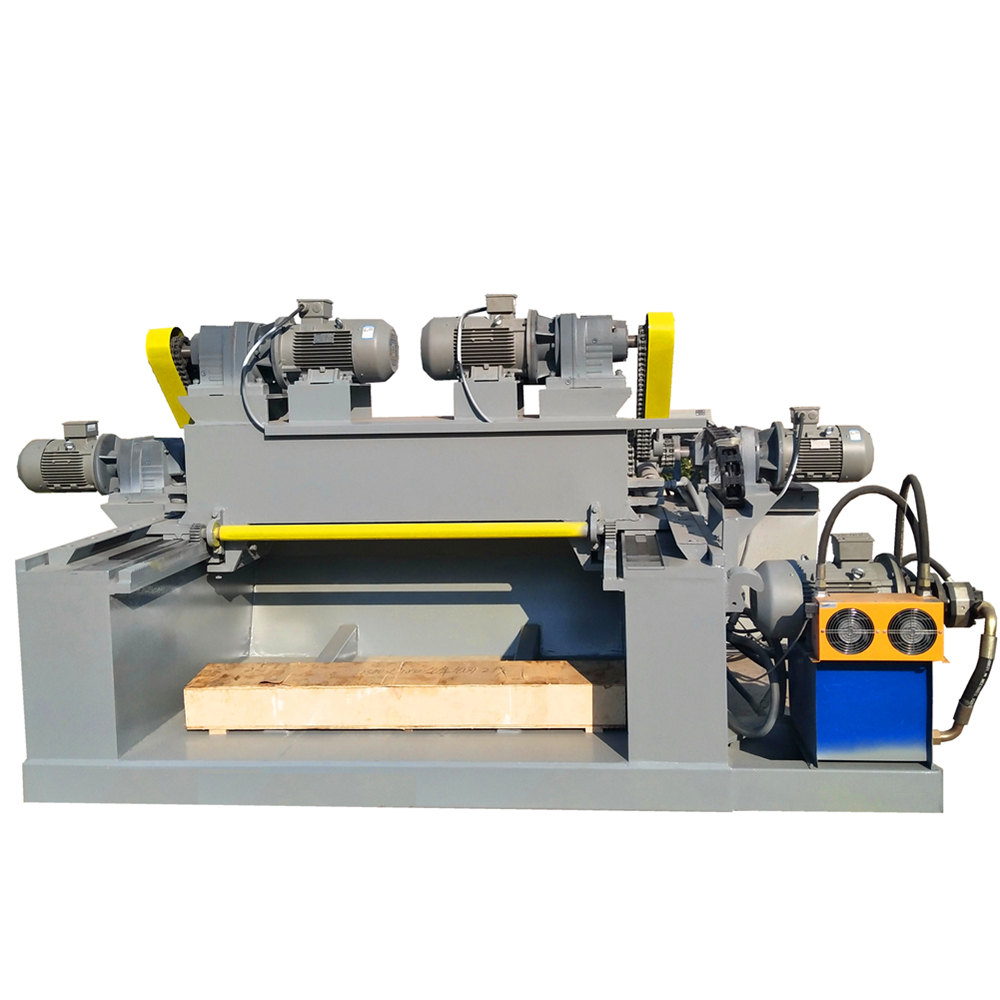

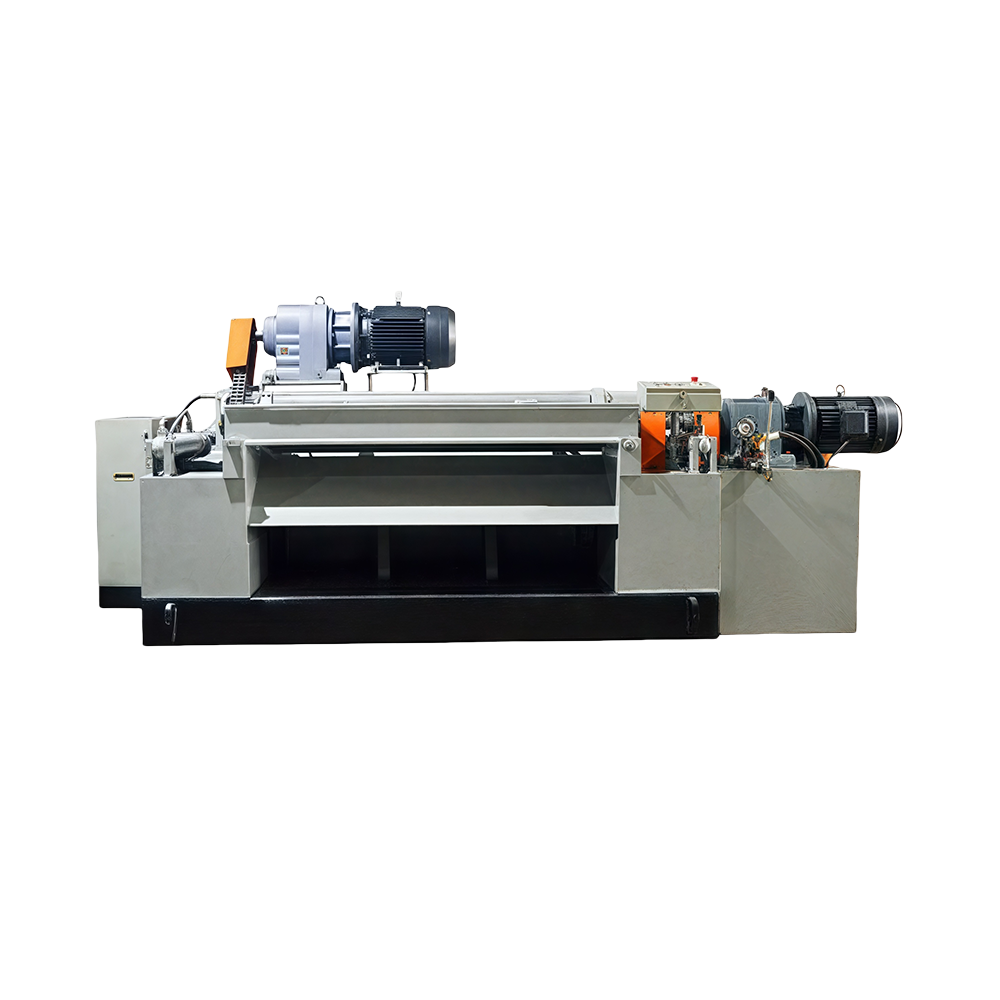

Tumble dryer

【Tumble dryer】

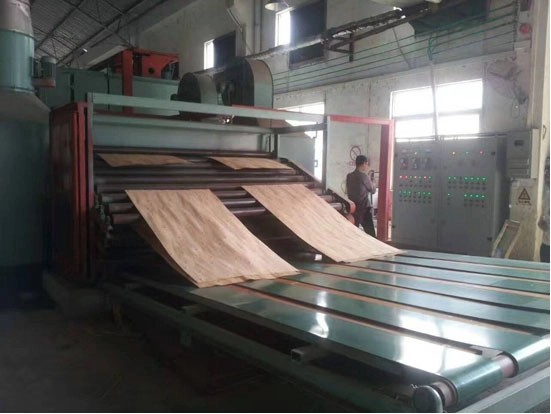

The veneer is heated by conduction through a continuously rotating hot drum and dried layer by layer

【Technical function】

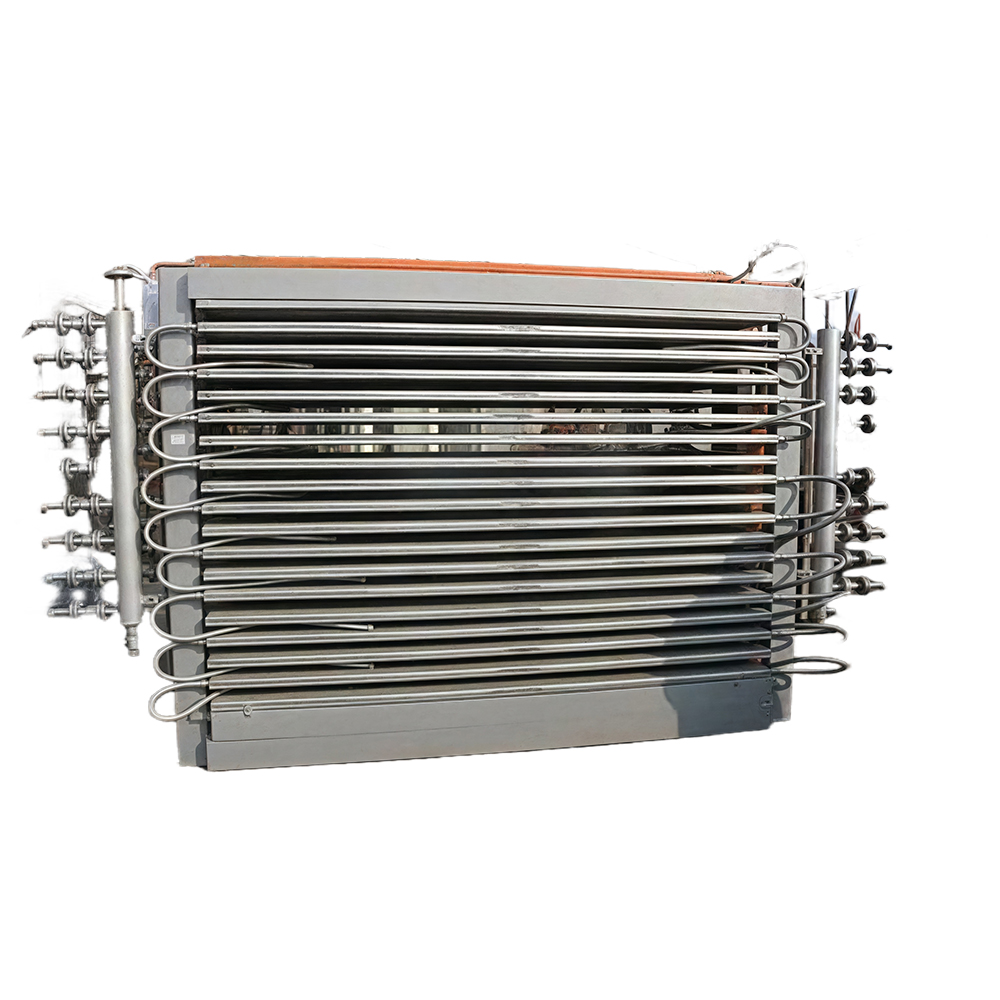

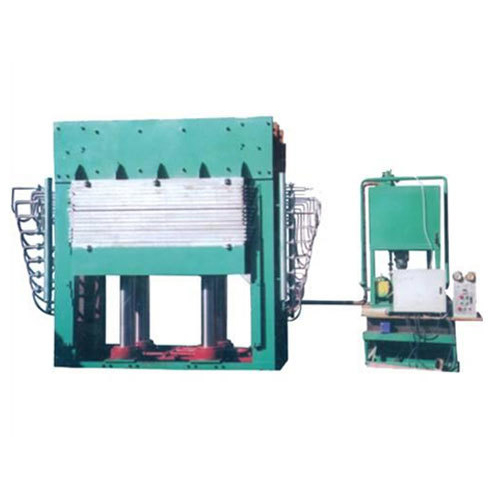

The dryer is composed of heat source system, conveying device, drying room, control system, drainage system and other parts, according to the different working principles can be divided into drum dryer, mesh belt dryer, hot air circulation type, vacuum dryer, mainly through the thermal action to reduce the water content of veneer (veneer), Make it from the high water content after spinning cut (about 30% to 60%) to the gluing process requirements of 8% to 12%, to ensure that the adhesive effective bonding, prevent the finished board warping, cracking or degluing, widely used in plywood, LVL veneer laminated wood, veneer processing and other industries veneer drying link.

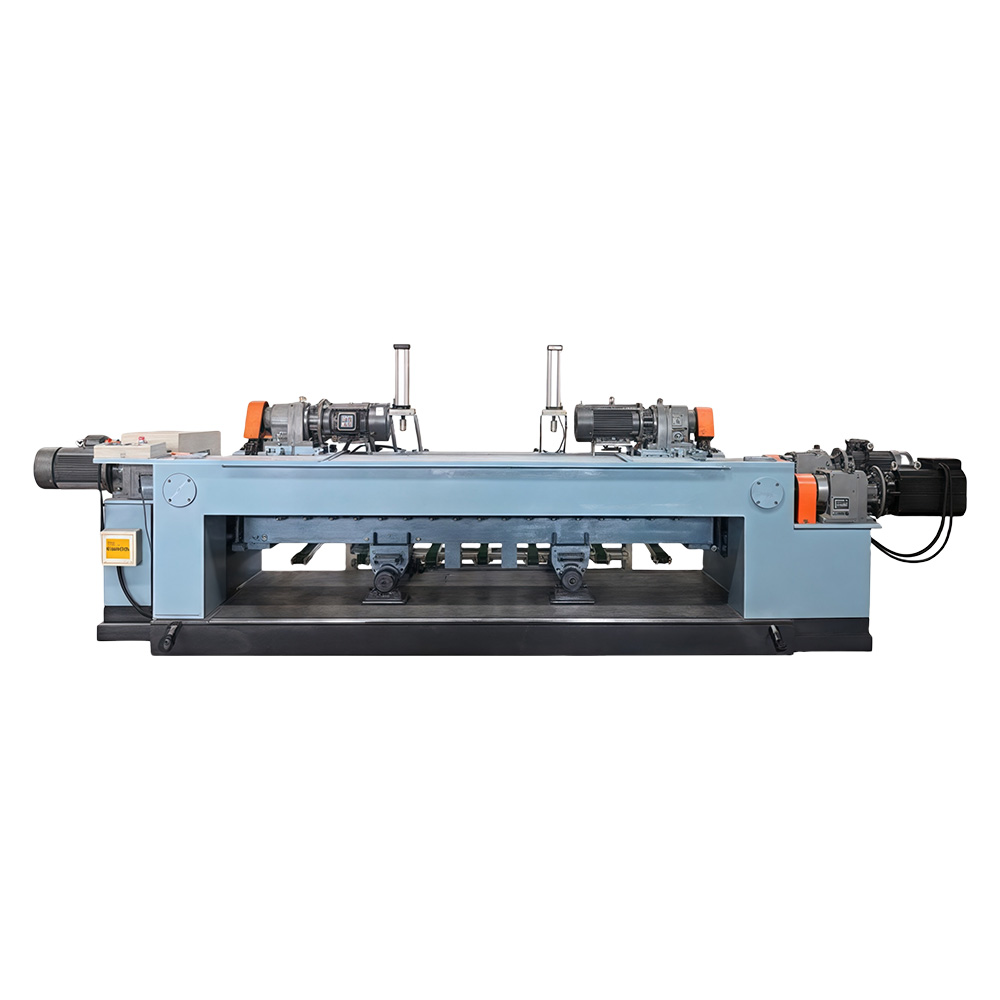

Product detailed parameters

Working width | 2800mm | Drying method | hot air, steam or hot oil |

Length of heating section | 10*3000=30000mm | Board thickness | 1-6mm |

Length of cooling section | 1*3000=3000mm | Moisture content before drying | 60% |

Total installed power | 90kw | Water content of the board after drying | <12% |

Transport | 11 kW * 1 = 11 kW | Dry capacity | 1.2 -1.6 cubic meters/hour |

Heating | 7.5kw * 10 = 75kW | Size | 33000 * 4400 * 2300 mm |

Cooling | 4 kW * 1 = 4 kW | Total weight | 34 t |

Feed speed | 1-30m/min | Personnel needed | 2 |

Product application value and advantages

【Quality assurance】

Precise control of moisture content to avoid delamination or deformation of plywood

【Efficiency improvement】

Continuous drying is more than 80% shorter than traditional drying time

【Energy saving and environmental protection】

Waste heat recovery technology reduces energy consumption, and waste gas treatment system reduces VOCs emissions

You Might Also Like