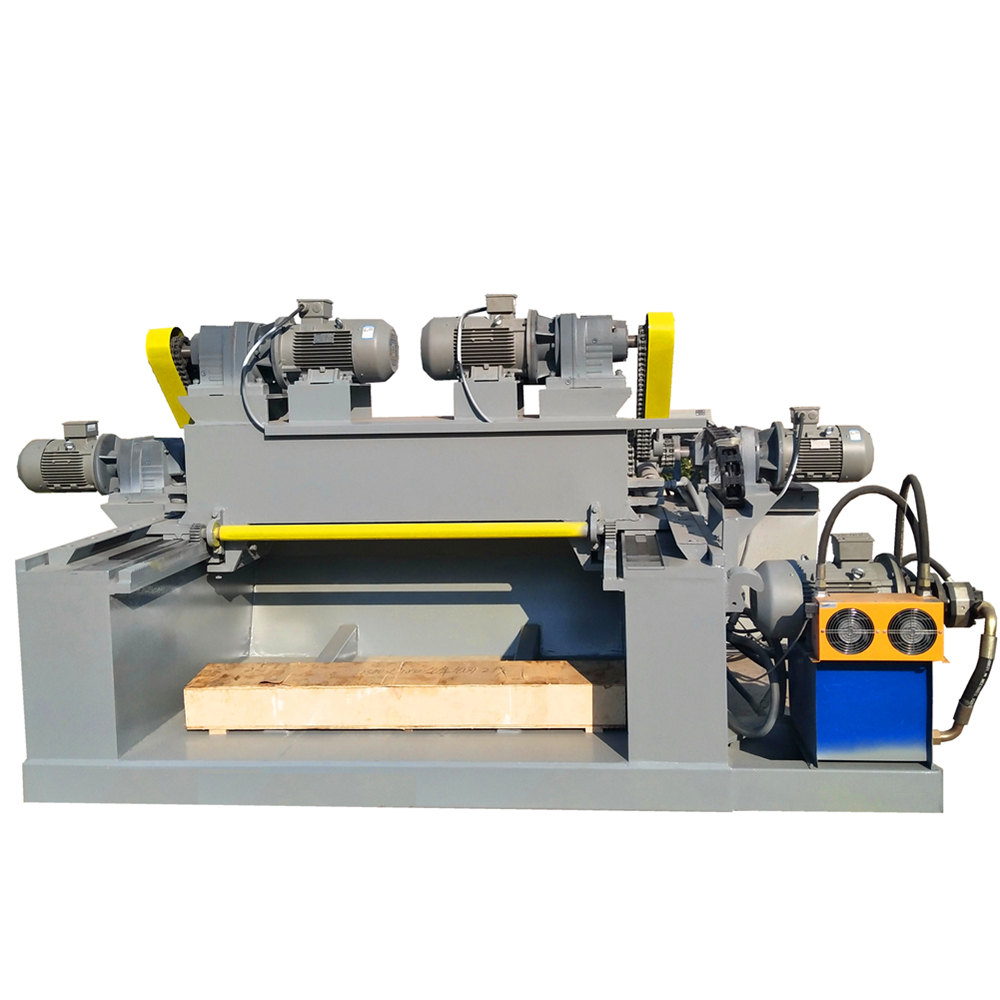

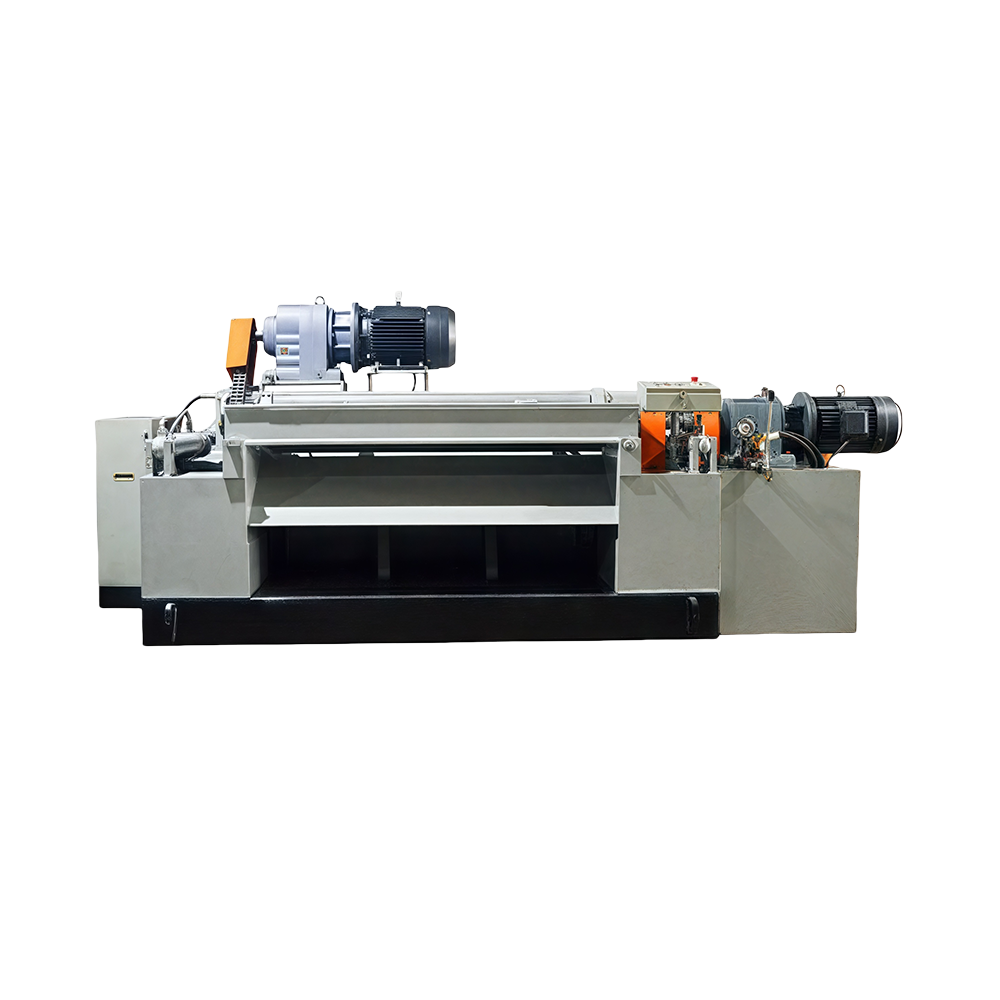

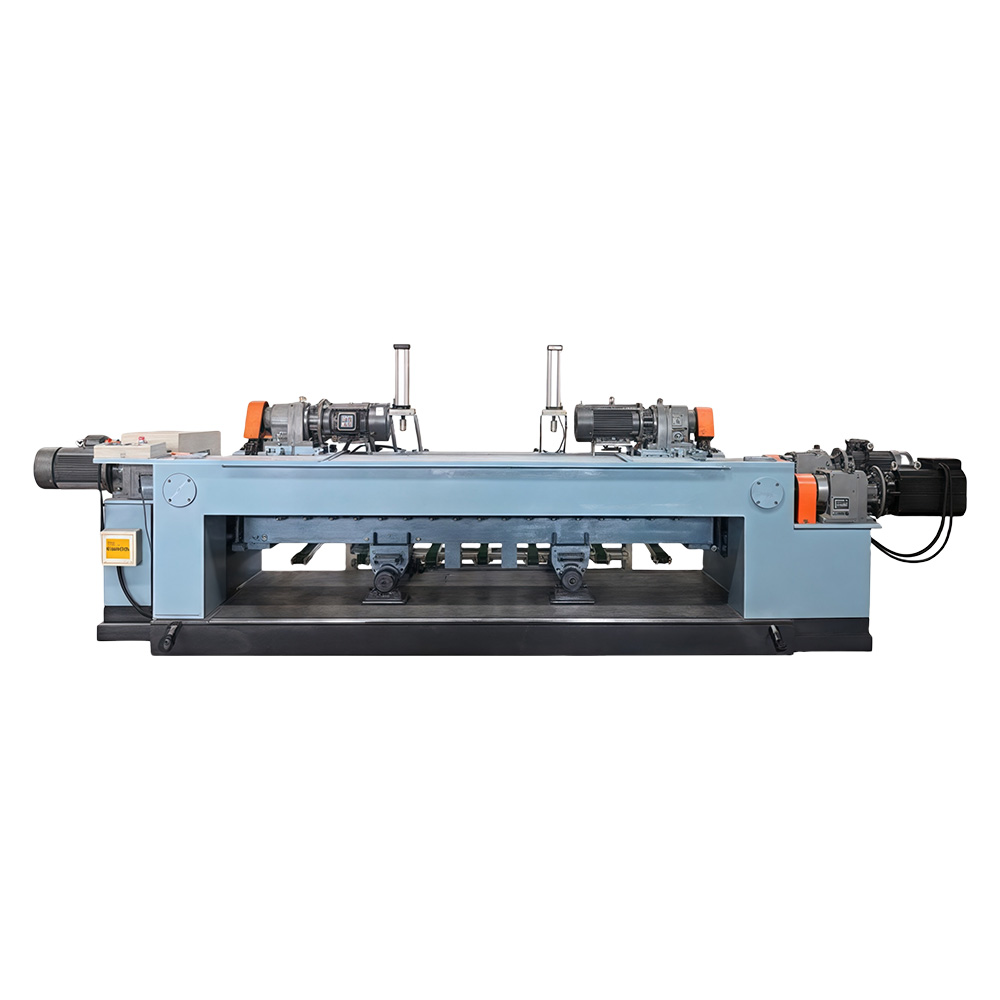

Cold press

【Technical function】

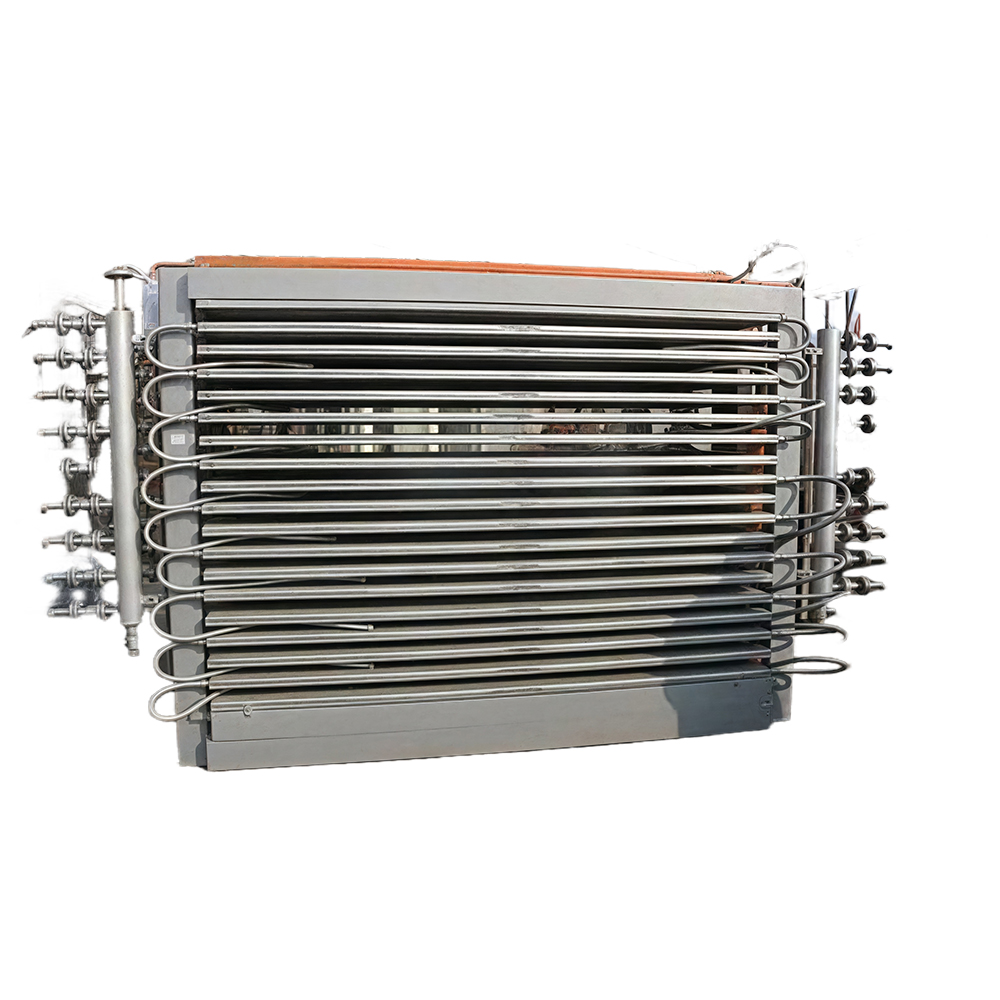

Cold press is a kind of equipment that applies pressure to the slab after gluing by mechanical or hydraulic device, it can make the adhesive in the slab uniform distribution and preliminary curing, enhance the bonding force between layers, prepress and flatten the slab, reduce the deformation during subsequent hot pressing, improve the dimensional stability and quality of plywood, suitable for the large-scale production of multi-layer plywood, joinery board and other plates.

Product application value and advantages

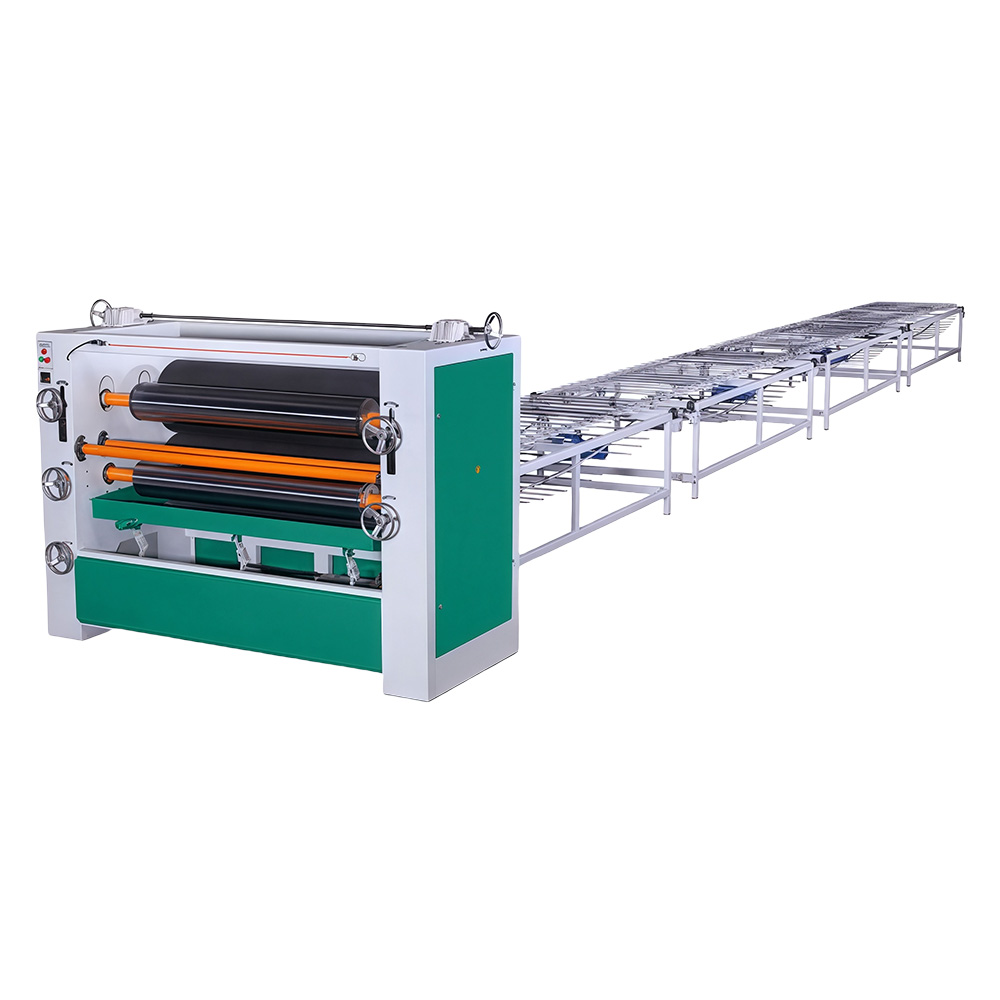

【Increased production efficiency】

Automated plate feeding and multi-layer cold pressing design can significantly reduce single batch processing time and reduce manual intervention

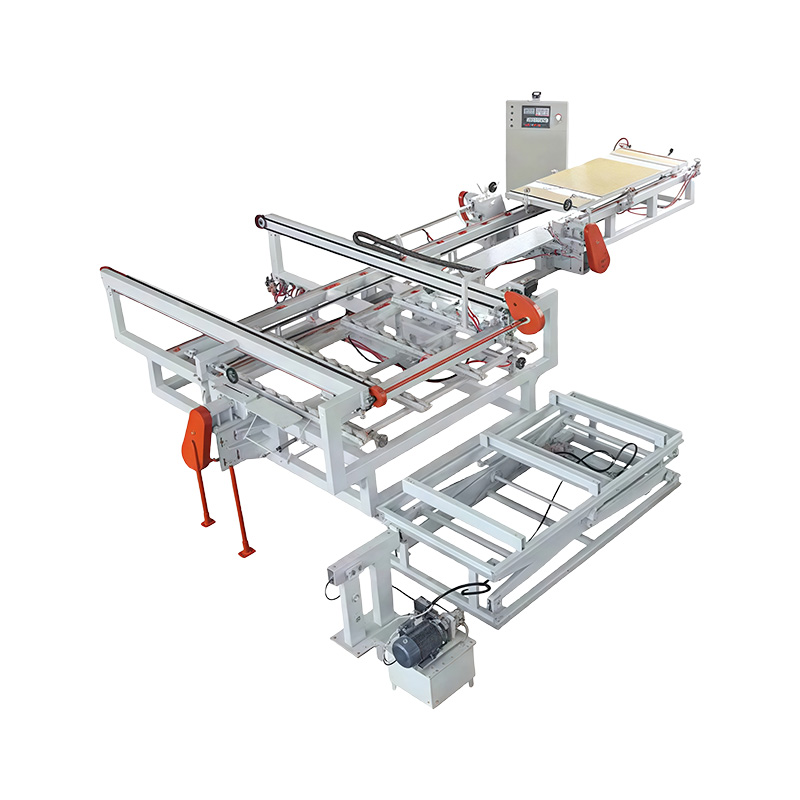

【Ensure product quality】

precise positioning mechanism and uniform pressure distribution to avoid misalignment or deformation of the slab

【Strong adaptability】

The pressure parameters can be adjusted according to the plate type to meet diverse needs

Product detailed parameters

|

Nominal pressure |

500T/ 400T |

|

Entry direction |

Transverse |

|

Medium space |

1800mm |

|

Working size |

2700x1370mm |

|

Cylinder stroke |

1050mm |

|

Pressure |

25mpa |

|

Frame thickness |

35mm |

|

Upper and lower beams |

900mm |

|

Middle drag |

400mm |

|

Total weight |

11500kg |

You Might Also Like