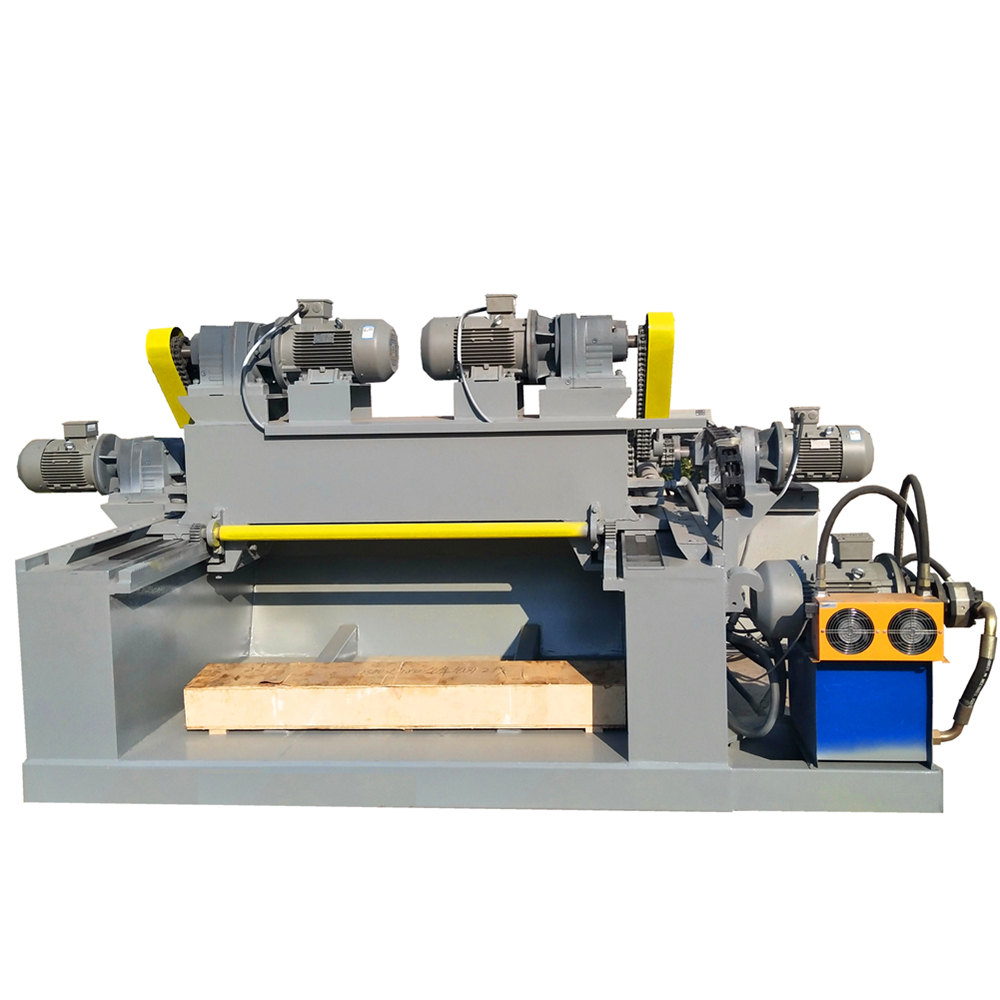

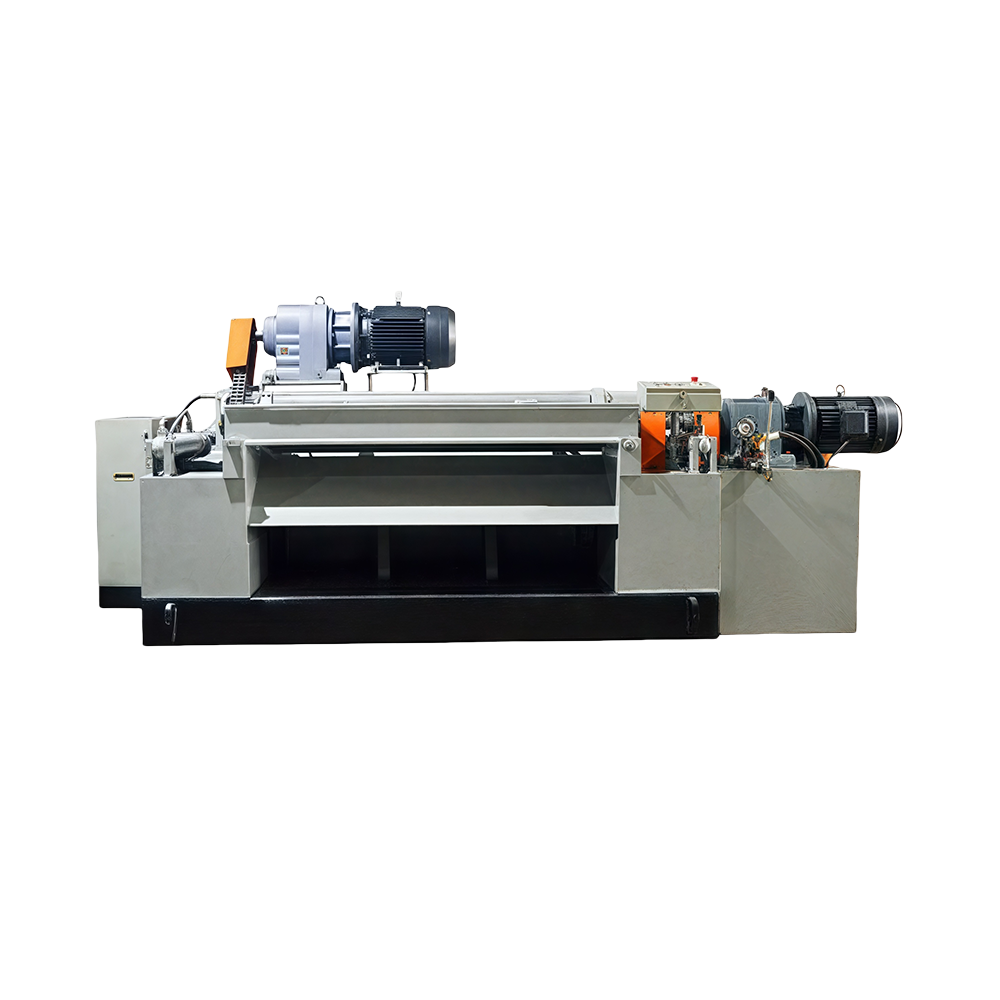

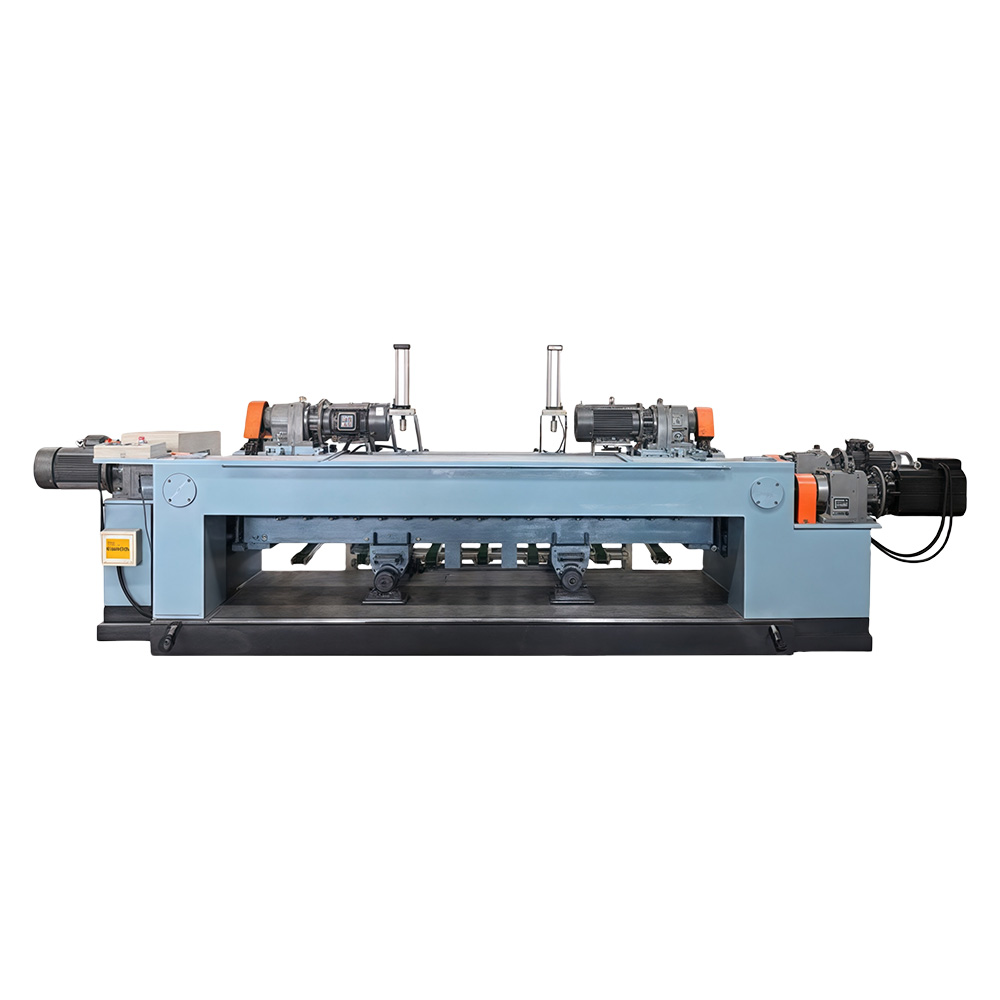

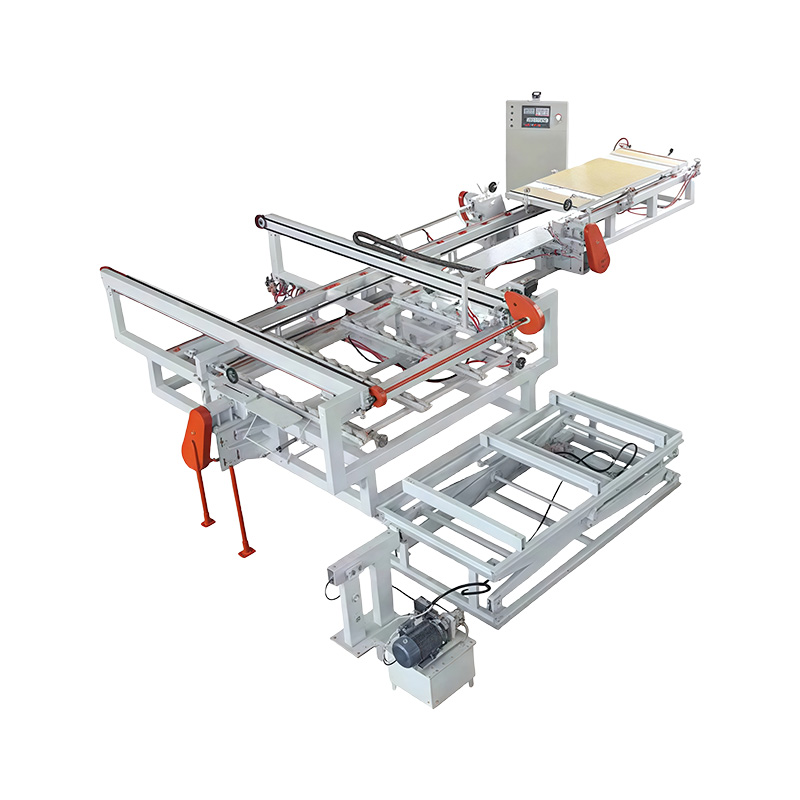

Roughing machine

【Technical function】

The embryo forming machine is composed of billet workbench, conveying mechanism, transfer and positioning device, taking and laying device, lifting system, control system and other parts, through mechanization or automation means, instead of traditional manual billet, to achieve precise positioning, conveying and laying of the single board, its core role is to improve production efficiency, reduce labor costs, and ensure the interlayer alignment and bonding quality of the slab. It is suitable for large-scale production of multi-layer plywood, joinery board, building template, etc.

Product application value and advantages

【High efficiency and labor saving】

The automatic billet greatly reduces the manual operation, can save more than 70% of the billet labor, while improving production efficiency

【Precision and quality】

Mechanical positioning and standardized processes ensure alignment between veneer layers, reduce misalignment and gaps, and improve slab bonding quality

【Strong adaptability】

Support a variety of board specifications and layers, some equipment can adjust the mold or program, flexibly adapt to different product needs

Product detailed parameters

Installed power | 43.8KW |

Efficacy | 5-7 sheets /min |

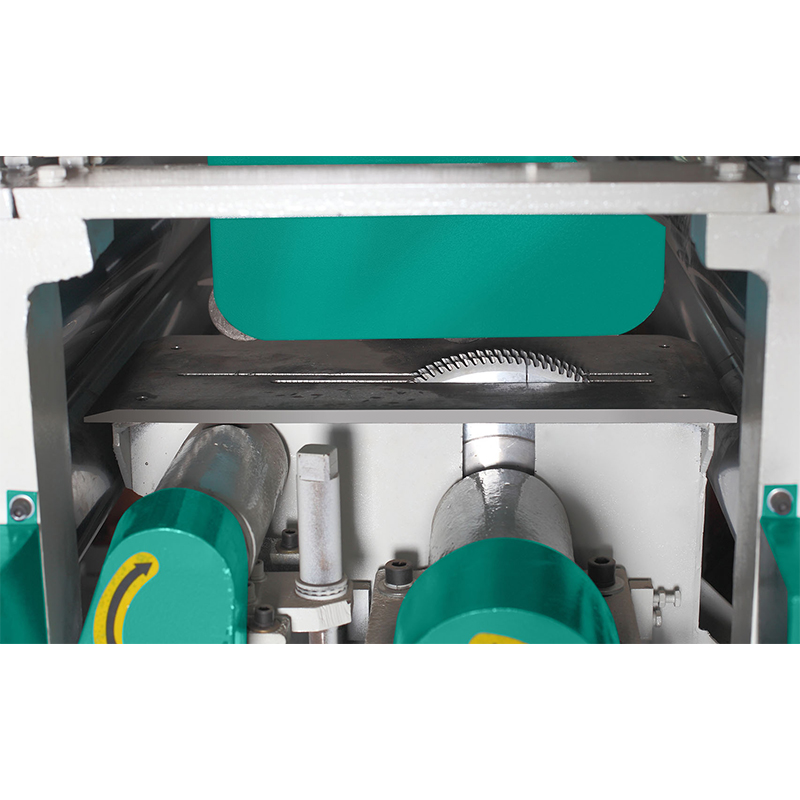

Knife length | 1400mm |

Inlet plate thickness | 1.2-4mm |

Overall dimension (length, width and height) | 9.6m*7.8m*2.5m |

Work site size | 10.6m*8.8m*2.5m |

Feed plate size | 1.33m*1.33m |

Exit plate size | 1.33m*2.66m |

You Might Also Like