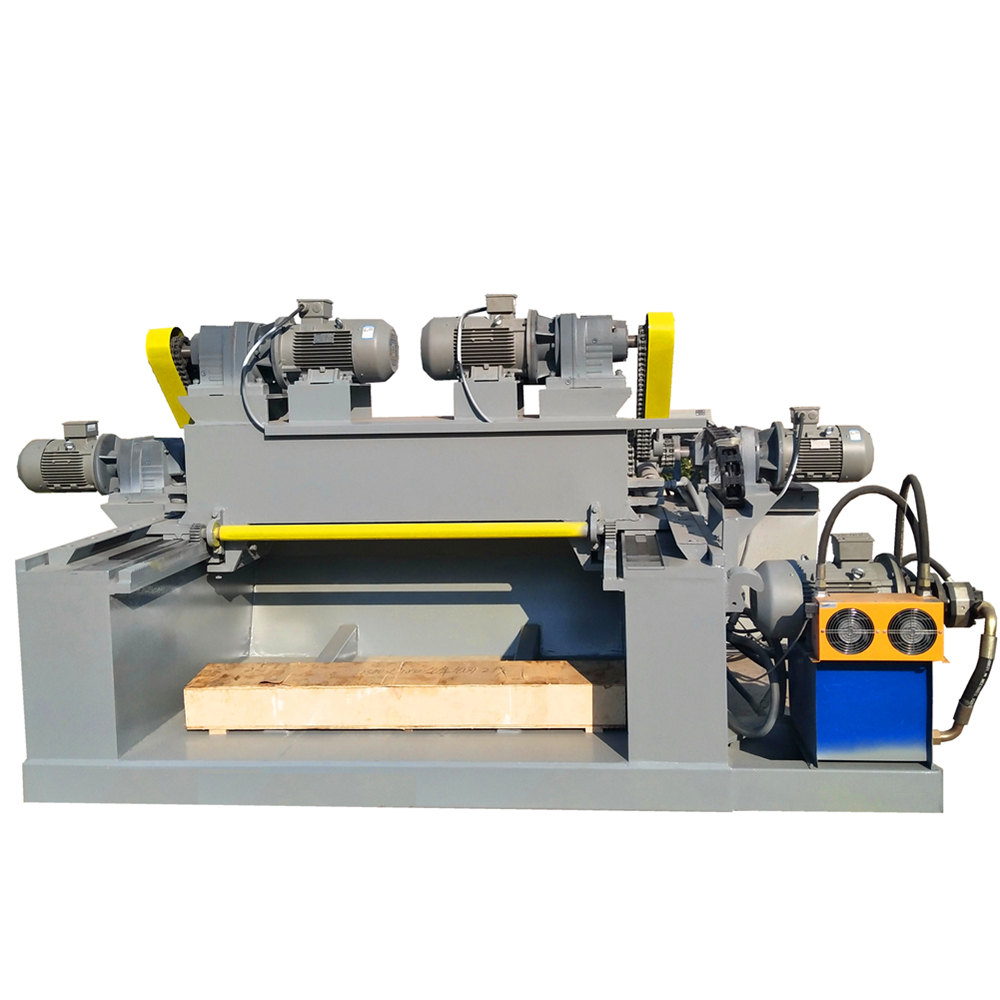

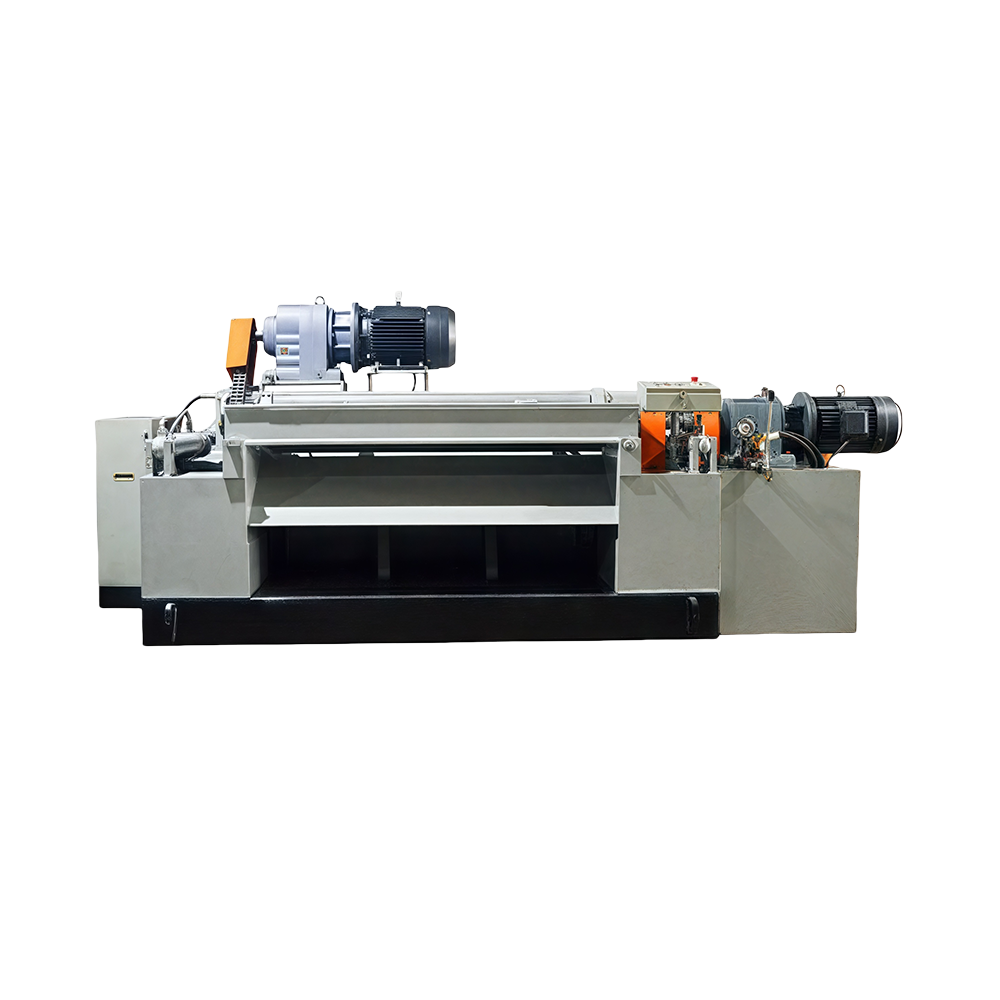

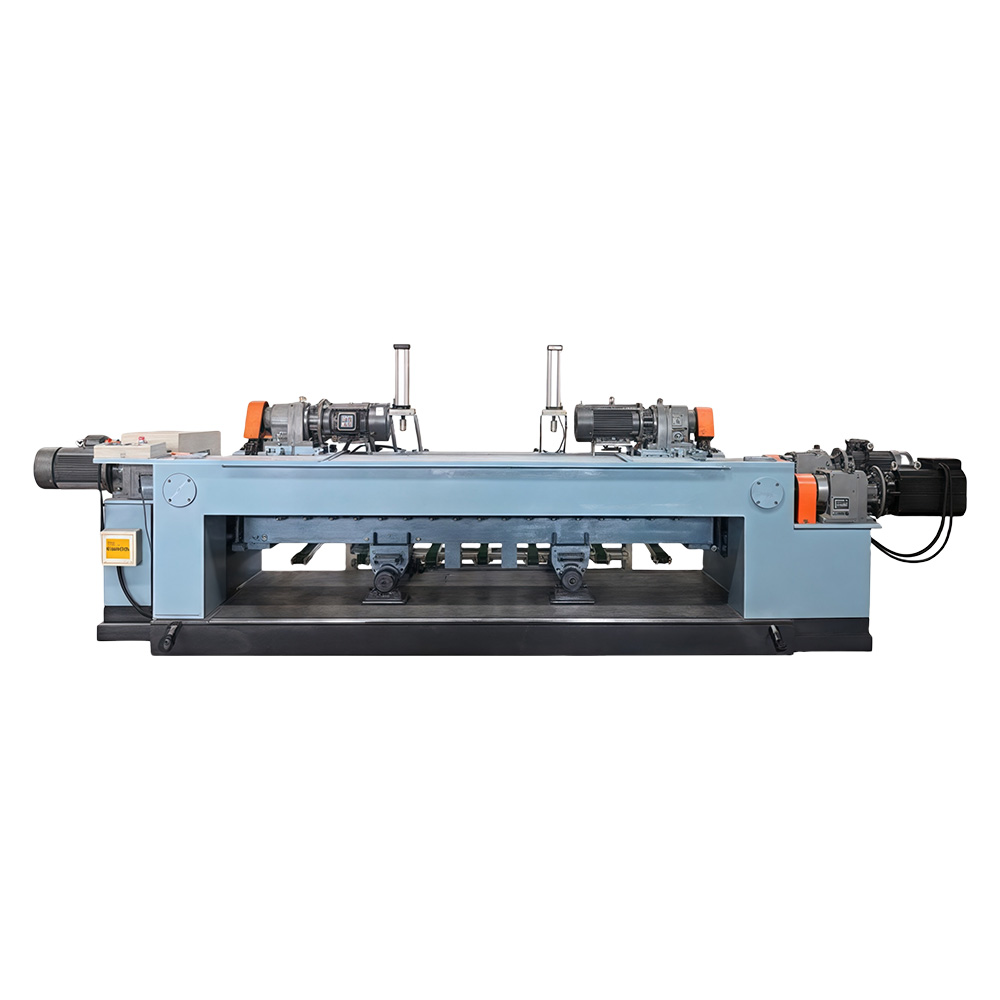

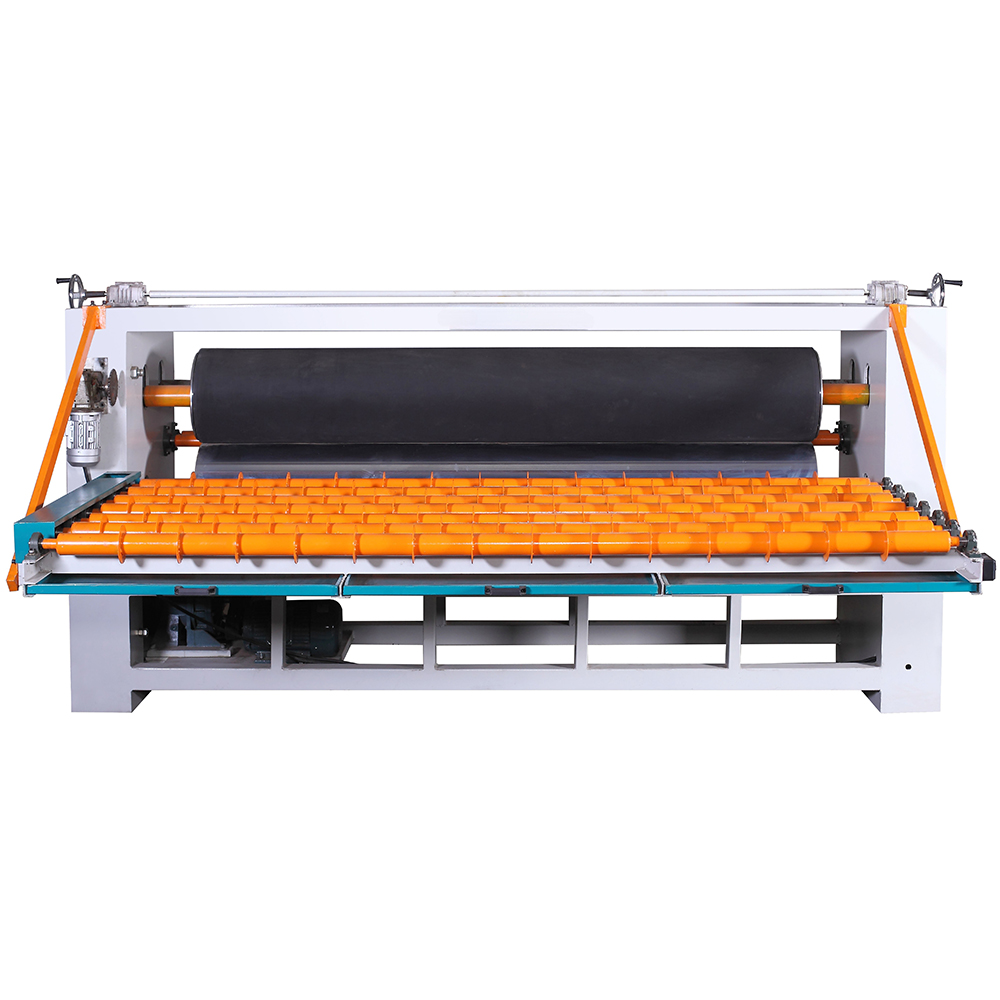

Gluing machine

【Technical function】

The gluing machine is usually composed of a frame, a gluing roller and a technical roller, a gluing groove and a gluing system, a transmission device, a adjusting device and other structures. The device uniformly applies the modulated adhesive to the veneer surface through a mechanical device. Its core function is to provide a stable and uniform adhesive layer for the subsequent hot pressing gluing of the plywood, so as to ensure the strength and quality of the sheet.

Product application value and advantages

【Strong adaptability】

Support different thickness of the veneer, roll surface groove design to optimize the distribution of glue, to ensure uniform coating

【High efficiency and energy saving】

high degree of automation, some models are equipped with bottom hopper design, reduce the frequency of manual gluing, improve production efficiency

【Stable structure】

the frame is made of steel structure or cast frame, and the roller material is mostly cast iron or steel pipe covered with hard rubber, wear-resistant and durable

Product detailed parameters

|

Max.spreading width |

2600mm |

|

Max.spreading depth |

90mm |

|

Dia of main roller |

Φ420mm |

|

Glue spreading speed |

0-55m/min |

|

Motor power |

7.5kw |

|

frequency drive motor |

7.5kw |

|

Outfeeding rack motor |

0.37kw |

|

Overall dimensions(LxWxH) |

3800*1400*2100mm |

You Might Also Like