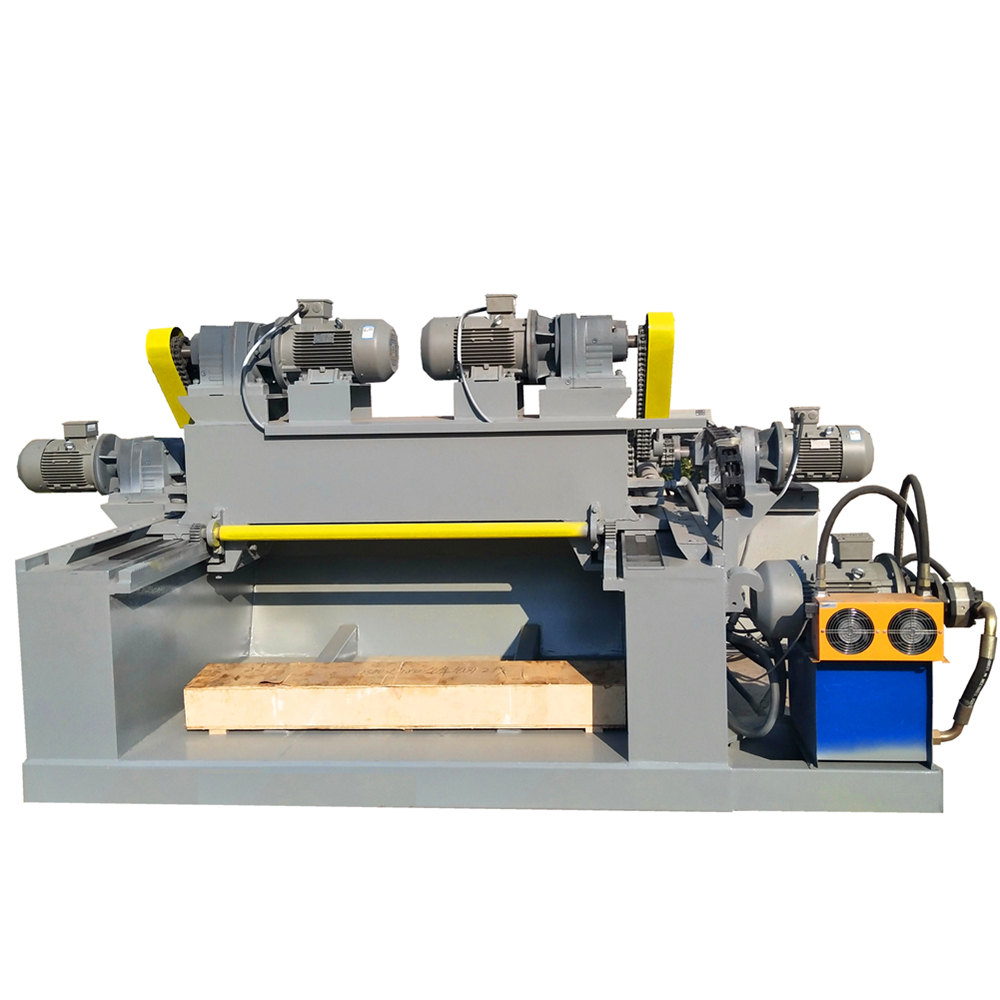

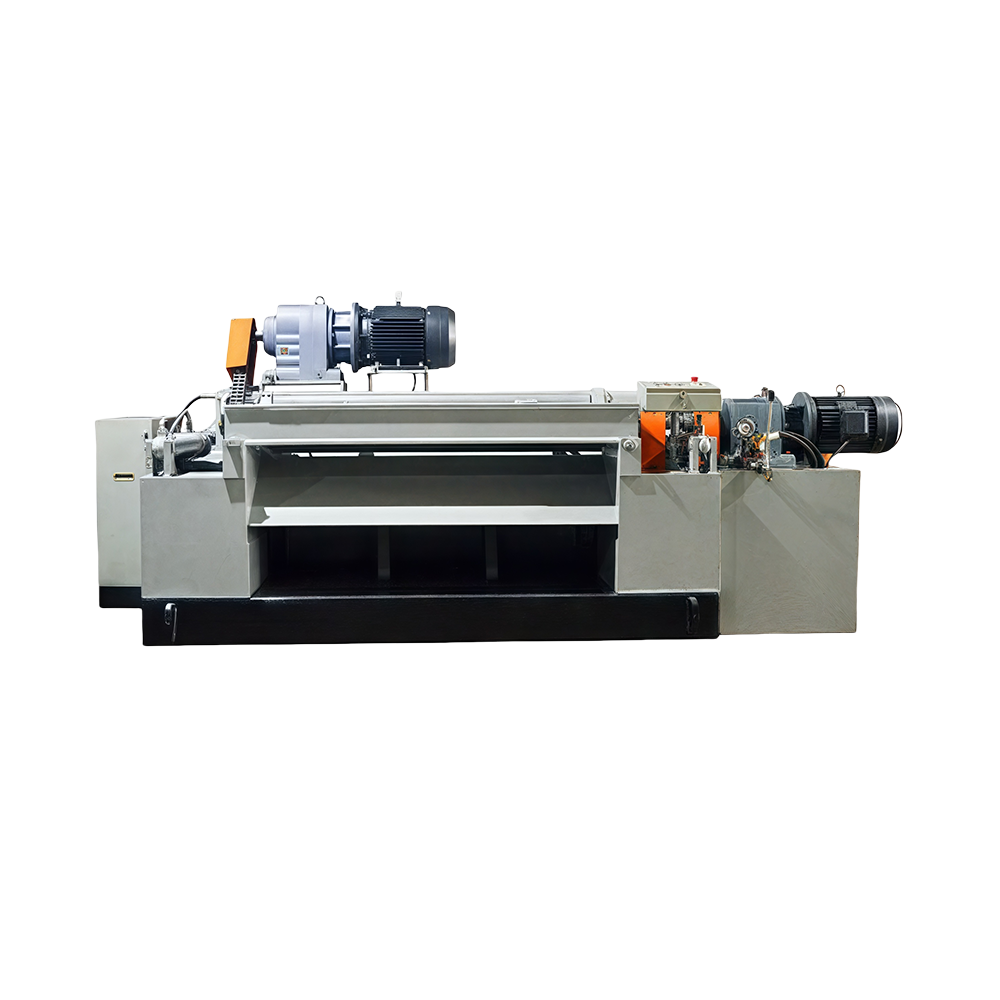

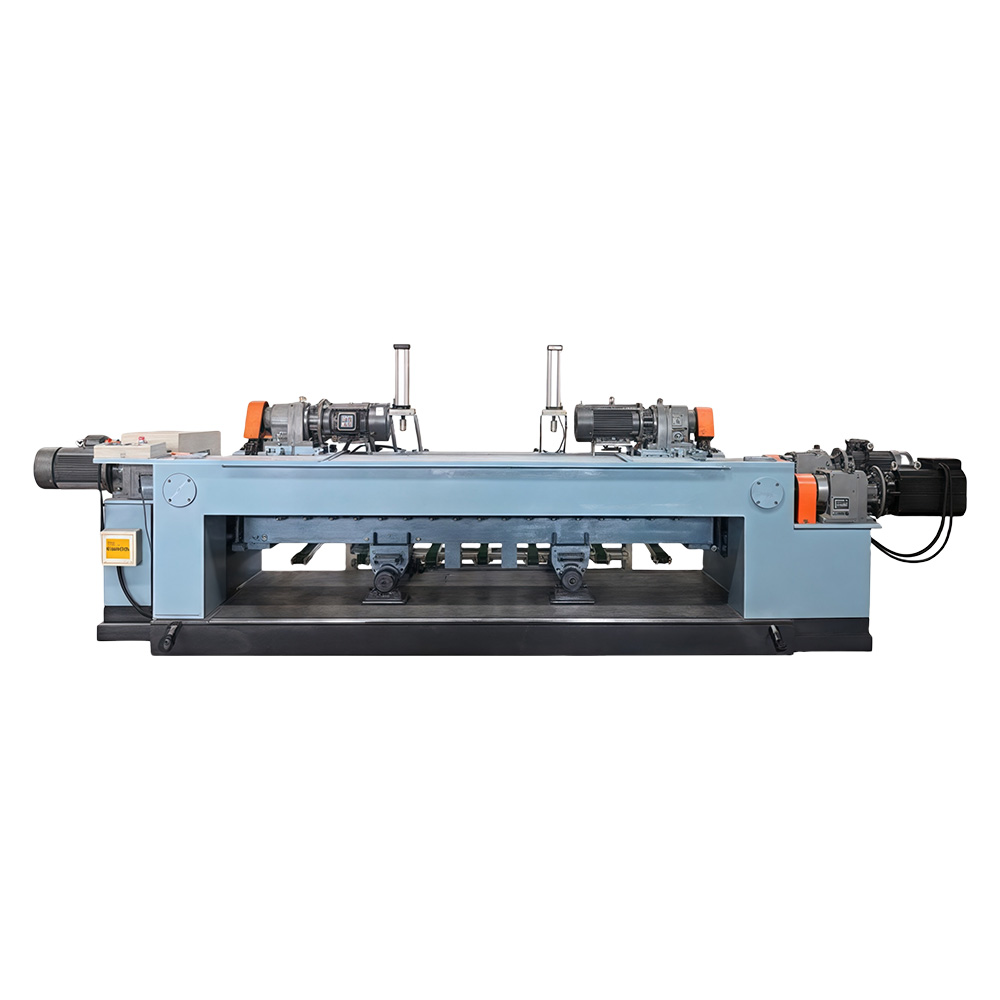

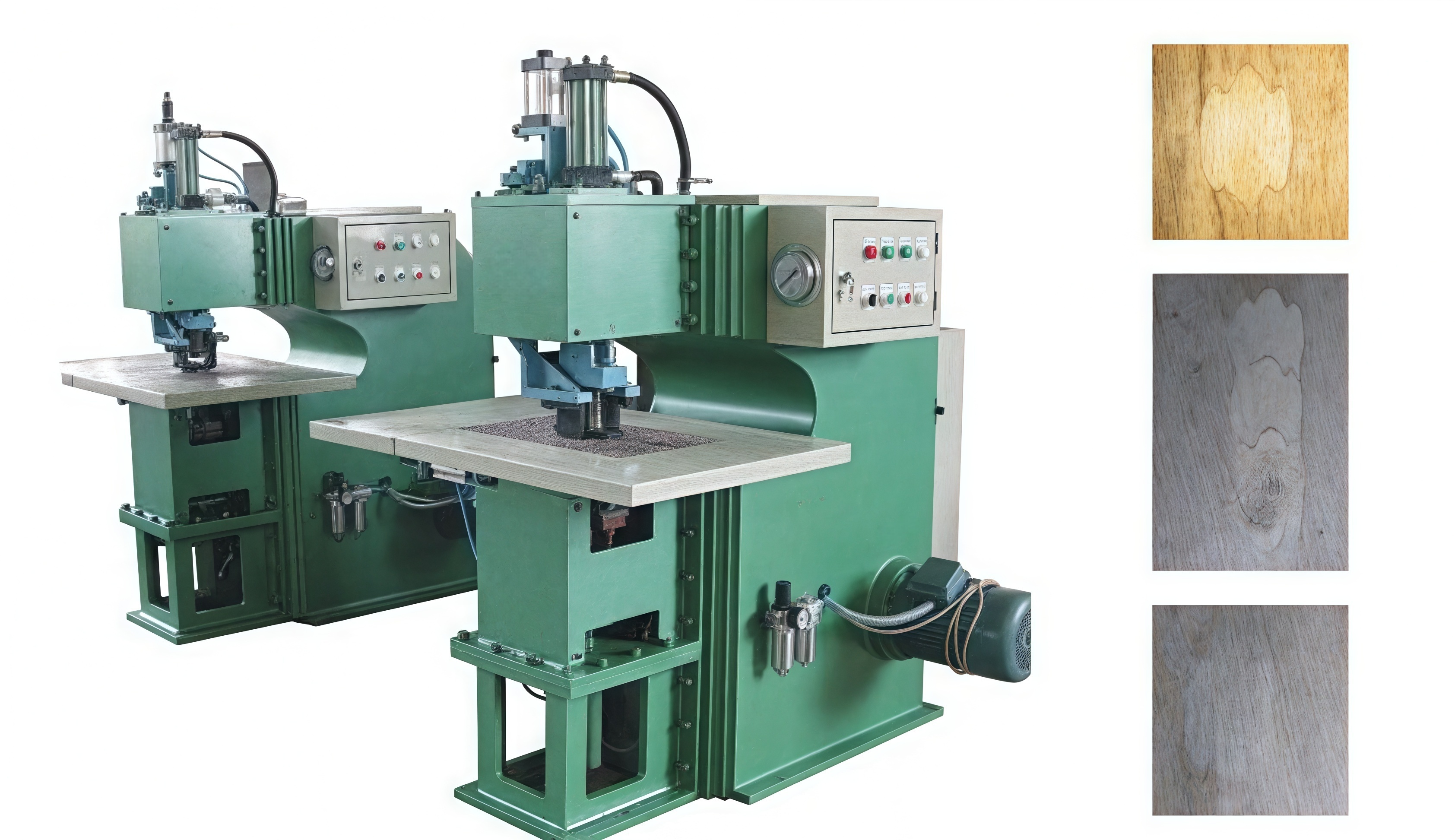

Punching machine

【Technical function】

Punching machine is usually based on the punching principle of the knife die, through the hydraulic or pneumatic system to drive the tool, quickly out of the plate defect parts of the regular shape of the hole, and at the same time to prepare matching patches, equipment is equipped with laser marking positioning system to ensure that the punching position is accurate. Automatic dredging machine adopts foot switch control punching, combined with infrared laser cross line positioning, can complete a blanking within 2 seconds, the efficiency is more than six times that of manual

Product application value and advantages

【High precision and high consistency】

the punched out complement is closely matched with the patch to avoid gaps after repair

【Easy and efficient operation】

Tool replacement is simple and fast, maintenance costs are low, and supports the customization of different shapes of molds to adapt to a variety of defects

【Automation and safety】

Some equipment adopts mechanical automatic stamping and planing technology to replace manual operation and reduce labor intensity

Product detailed parameters

|

Patch thickness |

0.8-3mm |

|

Repair board size |

40x60mm、60x100mm、70x130mm、90x150mm |

|

Motor power |

4kw、6kw |

|

Compressed air |

4-6kg/m2 |

|

Normal oil pressure |

16pma |

|

Cylinder diameter |

50mm、63mm、80mm |

|

Total size |

1650x1300x1750mm、1810x1500x1750mm |

|

Weight |

1300kg、1500kg |

You Might Also Like